|

Scratchbuilders

1/32 P-40 B/C Conversion (kit number 97002)

Text and photos Rogerio "Rato" Marczak

Actual aircraft photos by Scott Murphy

DO YOU WANT BUILD AN EARLY

HAWK?

Until some years

ago, there was no preserved early model of the P-40 in the world.

Now a few of them have emerged from several restoration projects.

The same thing happened to the P-40B/C Tomahawk in 1/32. Now

we have at least two choices, one of them is the subject of

this review.

Scratchbuilders has been recognized

for their good quality resin kits focusing on subjects that

will most likely never be released in injected form by a major

manufacturer. Contrary to their other offerings, which are complete

models, this one is a conversion to be used along with the venerable

Revell P-40E kit. Basically, the set provides a new fuselage

and nose designed to be matched with the Revell wings and tail.

Since the Revell P-40E is still around for less than 15.00 USD,

it won't be a problem.

The box art (Image: Scratchbuilders)

|

| OPENING THE BOX

The kit comes in

a sturdy box filled with peanut foams to avoid damage to the

parts (nice idea!) and they come in sealed bags. The conversion

consists of a hollow resin fuselage and nose, spinner, cooling

duct, armor plating, and instrument panel on which you glue

a printed instrument panel. White metal parts include the early

exhaust stacks, gun barrels and revised landing gear struts.

The clear parts are vacuum formed. Decals are by Scale-Master.

Here is the complete listing:

| Description |

Resin |

Metal |

Vacuform |

| |

|

|

|

| Fuselage

Assembly |

|

|

|

| Fuselage |

1 |

|

|

| Cowl |

1 |

|

|

| Reduction

Gear Housing |

1 |

|

|

| Air Duct |

1 |

|

|

| |

|

|

|

| Cockpit

Assembly |

|

|

|

| Armor Plate |

1 |

|

|

| Instrument

Panel |

1 |

|

|

| |

|

|

|

| Landing

Gear |

|

|

|

| Landing Gear

Struts |

|

2 |

|

| |

|

|

|

| Misc. |

|

|

|

| Spinner |

1 |

|

|

| Spinner Backing

Plate |

1 |

|

|

| Exhaust Stacks |

|

2 |

|

| Gun Barrels |

|

4 |

|

| Canopy |

|

|

1 |

|

Side Windows

|

|

|

2 |

|

Armor Glass

|

|

|

1 |

| |

|

|

|

| Total: |

8 |

8 |

4 |

Instructions are in the form of a descriptive text guiding the

modeler through the major steps. Read it carefully before starting,

as this is the better way to know precisely which Revell parts

will be replaced. General directions about the position of some

pieces are also given, and they will help you fit them properly.

Scratchbuilders' instructions also include two pages of drawings.

The first shows assembly sketches to assist the modeler with

the cockpit, tail and the bullet proof glass inside the windscreen.

It also helps to position the new wing panel lines and the guns.

The other drawing is a decal placement instruction for one of

the versions provided with the kit (you have to use the box

top art as a guide for second decal version).

This is what you get once you open the box

(Photo: Scratchbuilders)

|

|

The resin parts

are well molded, and virtually free of bubbles. The cream colored

resin is of a very soft type, allowing easy sanding/scribing/scrapping.

Scratchbuilders (I mean the company) did a good job on their

fuselage and nose molds, because the thickness of these parts

are very small considering the size of them. In my sample, a

couple of areas on the fuselage sides are translucent because

they are so thin. I suggest that you inspect your kit and reinforce

the inner side of these potentially dangerous areas with some

epoxy glue before starting. This will avoid the risk of cracking

them during handling. On the other side, the quality of the

metal parts is not that good. More on that later. Now, let's

take a close look at the parts.

|

| FUSELAGE

The resin fuselage

is cleverly engineered, and fits relatively well to the Revell

wings. There are very few spots to sand or remove resin excess.

I found no visible bubbles on my sample, but after sanding/scrapping

the flash, some of them may appear (it happened to me). The

panel lines are recessed but not very consistent, and some of

them disappear in certain areas.

An area of major

concern is the joint between the resin fuselage and the Revell

wing root. You need to sand and test fit the parts several times

to achieve an acceptable gap and minimize filling/sanding, but

this is understandable in view of the curved root of Revell

wing. The curved fairing on the leading edge of the wing root

will need a lot of putty, but this is an easy area to sand using

a flexible sanding pad. Leave this job to be done after the

nose is installed because more putty will be necessary around

the nose joint too. The gap in the lower wing/fuselage joint

is wider though.

The Revell tail

must be cut off and attached to the new fuselage, this is not

beyond the skills of an average modeler.

|

|

Fuselage

Detail shot of the fuselage area - Front cockpit and wing

root

Detail shot of the fuselage area - Rear cockpit

Detail shot of the fuselage area - Inside cockpit area

Wing root to fuselage joint

|

|

As for the accuracy,

the lines of the P-40B/C rear fuselage are the same of the P-40D/E,

except for the cockpit area, and the shape/dimensions are very

well captured there (I've used the drawings from the Detail

& Scale book, by Bert Kinzey). The recessed areas of the

rear windows are also correct, but there is no representation

of the fuel filler caps. These are very noticeable on the actual

aircraft. The first aid/radio compartment door on the port side

is there, but you should consider deepening it a bit with a

gentle rescribing for good effect. Some panel lines are missing

and you can scribe them very easily provided you have good drawings.

One of the hardest part of this review was to find reliable

scale drawings for the subject...and I'll tell you, they are

not many...

|

Checking fuselage accuracy

|

|

The blue position

light just above the wing fairing is represented as a recessed

circle, although not all early P-40's had it - check references

for the bird you are going to model. The photo below shows the

AVG veteran Erik Shilling in the cockpit of a fully restored

P-40B adorned with his markings.

|

AVG veteran Erik shilling remembering old times

onboard a restored Curtiss H81-A2 (photo:unknown)

|

| NOSE

The nose is the

most easy recognition point of the P-40B/C. Scratchbuilders

made a good job on the nose moldings, too.

For some reason,

not all break lines coincide with the panel lines, but you can

take advantage of this by not worrying in preserving the grooves.

Just fill the joint completely and sand. All the fasteners are

well represented in a countersunk fashion.

|

Nose

Checking nose accuracy

|

|

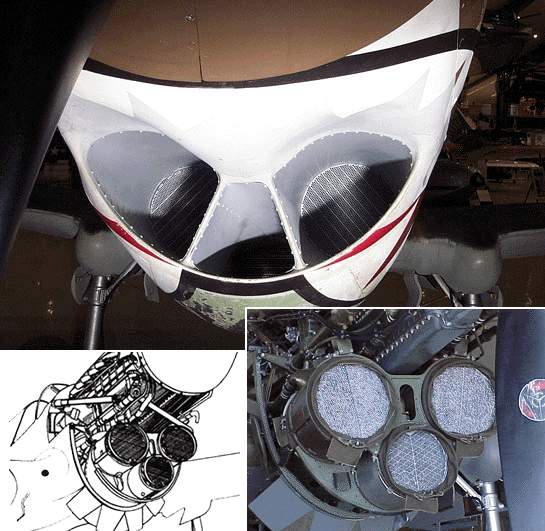

The circular carburetor

air scoop even has a visible screen inside. The 0.50" machine

guns fairing are well done and all you will need is to install

the gun blast tubes made of plastic tubing a few scale inches

out. There is a very thin resin skin over the stacks opening.

Remove it and sand smooth to accept the exhaust stacks. Turning

the part upside down, we find a well molded chin scoop for the

engine coolant and oil cooler (another characteristic of early

P-40's). However, comparing it to drawings and photos, it seems

that the chin is excessively deep (consequence of the bottom

nose area being too flat). That is the only fault in shape I

noted. Scratchbuilders included an air duct to be installed

from the inside, replacing Revell's part #11. Stick with Scratchbuilders'

instructions during this step. The air duct encloses the oil

cooler opening but not the radiator cooler ones. I guess that

a thin curved plastic card can do the job. We included a picture

of the P-40C on loan to the National Museum of Naval Aviation

in Pensacola, FL (USA), showing the arrangement when viewed

from the front - see below.

The Revell engine is to be used

replacing the crankcase with the resin one. This is enough to

account for the visual differences between the Allison V1710-33

of the P-40B/C and the V1710-39 of the P-40D/E. No removable

access panels here so you may be wondering why to use the Revell

engine. I suspect that this is to eliminate the see-through

effect when looking from the engine air intake or cooling flaps.

Also, it helps to align the crankcase shaft onto which the propeller

will be inserted. The Revell engine is then aligned by the crankcase

and the exhaust collars, so it won't be loose inside the cowling.

|

Detail shot of the nose - Carburetor air

scoop and 0.50" MG fairing

Detail shot of the nose - Radiators chin scoop. Compare

to the photo below to see that the openings are too high

NMNA P-40C - Front view of the radiators chin scoop. Courtesy

of Scott

Murphy

In the detail, the arrangement of the coolers from the P-40N

under restoration at Week's Air Museum (photo:unknown)

|

|

Moving aft, we

have the major point of deception of the kit, in my opinion.

The engine cooling flaps. After the "Pilot's Flight Operating

Instructions" (see references) the pilot must open these shutters

during the landing, and no mention is made to close them after

the engine shutdown. That's why so many wartime photos show

them open. Our problem is that this is a huge opening... you

can see the radiators backside, lots of plumbing and even the

engine block from there, as shown in the NMNA P-40C photo below.

In short, the area is screaming for detail if you want so. Unfortunately

the Scratchbuilders representation of the cooling flaps is very

crude. I would recommend you to cut off the flaps from the nose

and scratchbuilt new ones. Any attempt will give better looking

results than the kit part. Another option is to use the Eduard's

detailing set for the Revell P-40E, which comes with photoetched

flaps:

- Eduard Accessories

- Product #32017 P-40E Warhawk (for Revell kit).

A hint of the contents

of this set can be found at ARC's

instructions sheet library.

|

Detail shot of the nose - Radiator flaps

NMNA P-40C - Aft view of the radiators shutters. Courtesy of

Scott Murphy

|

|

The other parts

to be used here are the reshaped resin spinner and its back

plate. They will be installed along with the Revell propeller

later in the assembly. The white metal exhaust stacks are very

crude and most of you probably won't like it. The kit instructions

claim that you can use the later exhaust style which comes with

the Revell kit, but assert this with your references because

only the a few P-40C's used it.

|

Other parts for the nose area

The white metal early style exhaust stacks

|

|

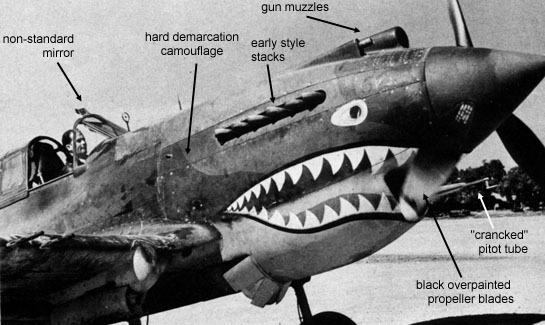

Now that we are

talking about the propeller, it is worth it to note that many

early WWII American aircraft had the propellers painted in black

on the back face of the blades only. The front faces were generally

left in natural metal. Seems insignificant, but this will determine

the color of the propeller stencils to be applied. Most stateside

early P-40s used that scheme as a factory finish. The black

was not applied on the entire blade, but some inches from the

blade root outwards, as shown in many photos. On the other hand,

it doesn't seem to be the case of British Tomahawks and, in

addition, there was field repainting, propeller substitution

for newer parts etc. The USN photo below shows a typical P-40C

in factory standard, while the AVG picture illustrates many

interesting details found in a front line machine.

|

A factory fresh P-40C (photo: National Archives)

A Flying Tiger wartime photo showing many interesting details

(photo: unknown)

|

| COCKPIT

The cockpit is

basically an adaptation of the Revell cockpit. For the detailers

this sounds like a too simplistic solution, because the cockpits

of B/C models had visible differences from the one of the E

model. A new resin bulkhead is provided to match the resin fuselage,

and the fit is good enough (clean it carefully). The characteristic

"inverted T" control panel is also given. You have to cut the

printed B&W control panel provided and glue it on the resin

part. This is a questionable approach for an open canopy. A

simple solution is to cut a thin plastic card using the resin

control panel as a guide and punch out the holes for the dials.

Paint this new front black and glue it on top of the printed

panel. There is no representation of the aft ends of the two

machine guns mounted in the cowling. Find something in your

spare parts box...

The major problems

of the cockpit are the Revell parts themselves, since the conversion

uses most of them, and they are very crude. The sidewalls, seat,

pedals, floor...everything is typical of a late 60's vintage

kit: the floor is flat and should be curved (the cockpit floor

of the P-40 was the wing upper surface), the seat is useless

and the sidewalls are wrong even for the E-model.. Jerry Rutman's

detail parts are handy here. Although they are intended for

the dash-E, some parts can be used/adapted for a dash-B/C. Check

it out in our J

Rutman accessories page or in a full

review by Brett Green, from Hyperscale. The seat for

the B/C model was the same that the one in the E-model, but

verify your references about the slight differences in the sidewall

consoles. Also, many PE parts of the Eduard set cited above

can be used.

Well, if you are

thinking of a detailed model, you have to do something here.

Besides the control panel, you will need at least a more convincing

seat as well as sidewalls with the proper modifications. I'll

leave you with some pics of the NMNA P-40C cockpit in case you

need a starting point. I also scanned a few pertinent details

from the "Pilot's Flight Operating Instructions".

|

Resin control panel and bulkhead

The printed control panel

Control panel of the NMNA P-40C. Courtesy of Scott

Murphy

Left sidewall of the NMNA P-40C. Courtesy of Scott

Murphy

Right sidewall of the NMNA P-40C. Courtesy of Scott

Murphy

Some cockpit details from the "Pilot's Flight Operating Instructions"

|

| GUNS

One of the high

points of the conversion, the wing mounted gun muzzles are provided

as white metal parts and they are exquisitely molded. Take care

during handling/cleaning because the metal is quite soft, some

of them were bent in my sample. Just roll each one on a flat

smooth surface to make them straight.

The instructions

sheet include a 1/32 drawing of the bottom wings showing the

correct positions of the wing guns and the spent casing chutes,

a bit crude but correct. This drawing makes the task much easier

in case you don't have your own plans in 1/32 scale (the P-40B/C

had two 0.30" guns per wing, instead of the three 0.50" found

in later versions).

|

The white metal wing mounted gun muzzles

|

| LANDING

GEAR

The white metal

main landing gear legs are one of the poorest parts of the conversion.

The instructions claim that they have the correct length. This

is because the Revell landing gear is designed to be retracted.

Had the legs had the correct dimension the wheels wouldn't fit

into the wells. However, the white metal legs provided are just

lengthened metal copies of the Revell parts. Considering the

somewhat crude casting of our sample, it seems better to lengthen

the Revell legs.

The actual P-40

landing gear was an engineer's dream, full of mechanisms and

hinges to rotate the wheels in order to fit them into the bays.

An expert modeler will test his skills to scratchbuild a landing

gear of that complexity, as Revell representation is very symbolic.

Even the doors lack the proper details. Again, the J

Rutman accessories set will save a lot of time here,

as it comes with a complete new landing gear - including the

wheel bays - to fit inside the Revell wing. Our friends from

LSP staff reported that the set fits very well.

I included one

more picture of the P-40C at NMNA along with some drawings to

help on this area. If you are going to the make your own details,

you can save some work by depicting a canvas covered wheel bay

and a tail wheel with canvas boot. The canvas was factory standard

to avoid dirt and dust entering the wing, but they were prone

to tearing under heavy use, so that they were generally removed

by the crewman.

|

Main landing gear white metal parts

The main wheels retraction mechanism and strut of the NMNA P-40C.

Courtesy of Scott

Murphy

|

| CLEAR

PARTS

There are 3 vacuum

formed clear parts for the canopy, incorporating a bit overdone

frame lines. The rear windows are not flat, but curved - as

they should be - following the fuselage cross section. All parts

are very translucent and made of a material called Zivac. The

instructions claim that bonding agents like Tenax-7R will work

with that material. I tested Tenax-7R in a previously trimmed

test stripe and it actually reacted with the material. On the

other hand, Humbrol and Testors liquid cements didn't even stain

the sample. Be warned then...

The sliding part

comes attached to the windscreen, a careful trimming will be

necessary to pose it open. Even if you are not going to cut

them apart, I recommend you to turn the part up side down and

then pour some plaster until the cavity is filled. Wait the

plaster dry and trim the borders. This will give you a more

stiff surface to run the knife. Once done, pop the plaster block

out of the clear part and rinse with water.

|

The clear parts

|

| DECALS

Two versions can

be made out of the decal sheet:

- Curtiss H81-A2

s/n P-8173 flown by the AVG ace R. T. Smith. This is the famous

#77 seen in many AVG wartime photos.

- Curtiss Tomahawk

AK498 flown by the 250 Sq. ace Clive "Killer" Caldwell during

the Africa campaign.

There are many

important notes about the correct use the markings. Read the

instructions carefully. For instance, the Disney's Flying Tiger

is included in the sheet, but it was not used on #77. A nice

touch is the pair of Chinese roundels to be used on top of the

wings, which are printed in a slightly toned down blue to simulate

fading (always more aggressive on top surfaces). You must follow

Revell instructions for the stencil locations, although the

numbers don't match (this is clearly noted in the instructions

too).

As for the quality

of the decals, they are very good, but my sample had the red

layer out of register. This is not noticeable except for the

red circles inside the eyes above the shark mouth. It didn't

pass by Scratchbuilders quality control because they kindly

provided a separated pair of eyes to replace those defective.

The decals are

produced by Scale Master with the popular Invisa Clear system.

If properly applied, I don't believe they will reject any setting

solution or present silvering problems.

|

The decal sheet

A zoom on the decal sheet details

AVG ace R. T. Smith showing his five kills tally. Rangoon, Burma,

late 1941

|

| FINAL COMMENTS

Many modelers claim

that the real Flying Tiger was the P-40B/C. Personal tastes

apart, you won't have many choices to make an early hawk in

1/32. And there are many options to choose from for this conversion.

If you don't want to stick with the R. T. Smith bird, you can

choose one among the AVG famous pilots: Dick Rossi, Charlie

Bond, "Tex"Hill, Charles Older, Erik Shilling and even Gregory

"Pappy"Boyington. Although the Disney's Flying Tiger is provided

in the decal sheet, most AVG P-40s used to wear some sort of

artwork. This can be a problem unless you choose a machine from

the first days of the group (initially AVG squadrons flew plain

H81-A2 with just the fuselage numerals ad no elaborate artwork).

Whatever the case, remember that the AVG machines were Curtiss

Hawk H81-A2 (similar to the P-40C) which had been built for

export to Britain. As a consequence the pitot tube must be of

the cranked type and the factory applied colors didn't match

perfectly the usual RAF Dark Green/Dark Earth/Sky cammo.

Reportedly, Curtiss used DuPont Dark Green 71-013 and Dark Earth

71-009 for upper surfaces and possibly Light Gray 71-021 for

undersurfaces. The question about the best FS matches of these

colors is still open and you are on your own here. Moreover,

AVG aircraft were generally heavily weathered, given the nasty

conditions they operated (see photo below). All I can suggest

you is to read the good discussion on the subject in Bridgewater's

recent book (see references). If you are going to a British

Tomahawk, the same comments apply. As usual with limited run

kits, you won't find aftermarket decals for this bird (that

I'm aware of).

|

A widely published color photo of AVG flying

formation

|

|

A good notice is that the conversion

can be used to make a P-40-CU - the very initial version with

lighter armament or finish it as a pre-war stateside P-40B.

Ok, they were just olive drab 41 and gray, but I think what

will make such a model different is the version. After all,

an aviation aficionado will promptly note the differences from

the original Revell kit.

Other interesting

possibilities are those "Pearl Harbor defenders" stationed at

Bellows and Nichols fields during the attack (some of them actually

engaged the Japanese and downed a few) or the desperate fighters

of the 20th Pursuit Squadron at Clark Field, Philippines during

the first days of the war. Now if you want something very unusual,

there was the P-40B used by the Russians.

Turning back to

the conversion, I think that the only problem with it is the

Revell kit itself. I didn't covere here all the work you have

to do with the cockpit, landing gear, wings and tail to leave

the Revell parts accurate because this will be addressed in

another review. I'm not saying it is a bad kit, but it includes

some toy like features which result in serious inaccuracies.

The Scratchbuilders bits will do their part. I can anticipate,

however, that the raised panel lines in the Revell parts are

not consistent with the recessed ones in the resin fuselage

and nose.

|

Curtiss test pilots Herb Fisher (left) and Ed

Elliot prior to test flying several brand new P-40B fighters

(none have guns installed)

|

|

Other important details are

the pitot tube, which must be cranked for British and AVG machines

(the boxtop artwork is wrong on this) and straight for the American

ones. Also, there's no gun sight ring or mast, but they can

be stolen from many photoetched sets. Don't forget to install

these items in offset with the fuselage center line.

My references for

this review were:

1.) McDowell, E.

R.: Curtiss P-40 in Action, Squadron Signal Publ., 1976.

2.) Kinzey, B.:

P-40 Warhawk in Detail - Part 1: YP-36 through P-40C, Detail

& Scale Vol.61, Squadron Signal Publ., 1999.

3.) Kinzey, B.:

P-40 Warhawk in Detail - Part 2: P-40D through XP-40Q, Detail

& Scale Vol.62, Squadron Signal Publ., 1999.

4.) Drendel, L.:

P-40 Warhawk Walk Around, Walk Around Number 8, Squadron

Signal Publ., 1996.

5.) Famous Airplanes

of the World, No. 39: Curtiss P-40 Warhawk, Burindo, 1993.

6.) Bridgewater,

H. C.: The Curtiss P-36 and P-40 in USAAC/USAAF Service - 1939

to 1945, Combat Colours Number 3, Guideline Publ., 2001.

7.) Bridgewater,

H. C. and Scott, P.: Pearl Harbor and Beyond - December 1941

to May 1942, Combat Colours Number 4, Guideline Publ., 2001.

8.) Technical Order

No. 01-25CF-1: Pilot's Flight Operating Instructions - P-40D

and P-40E Airplanes, AAF Headquarters, Air Service Command,

Patterson Field, Fairfield OH, Feb 1943.

9.) P-40 Fighter

Manual, AAF Headquarters, Office of Flying Safety, 1943.

The last two are

more difficult to obtain but the others are easily found

|

The Tomahawk as delivered by Curtiss to the RAF.

Note the cranked pitot tube and the longer blast tubes

|

| SUMMARY

As I mentioned,

the major problem with this conversion is Revell kit. Had Scratchbuilders

provided a complete cockpit I would rank it four stars - no

doubt. For you early hawks fans the only other option is the

Craftworks P-40C, but costs 125 USD!!!

This model is an

excellent choice if you want to try a resin model in 1/32 for

the first time. It is relatively easy to build and the finished

product will fill a huge gap in any collection of American WWII

aircraft.

By adding some

details and correcting the most obvious Revell flaws, I'm convinced

you will have a lot of fun and the result will be a truly unique

model.

|

This is the result (Photo: Scratchbuilders)

|

| ACKNOWLEDGMENTS

We would like to

thank the support Forrest Cox, owner of Scratchbuilders, for

providing the review sample. Also, our "inspiring master" Scott

Murphy for consenting the use of his NMNA P-40C walkaround

photos.

|

| ©

'Rato' Marczak

2002 |

|